Three phase motors are a type of AC motor that operates using the principle of electromagnetic induction. They differ from single-phase AC motors in that they use three-phase power, which provides smoother torque and higher efficiency. For a thorough understanding of three-phase induction motors, one must first possess a solid foundation in basic electrical knowledge.

They are among the most widely used electric motors in industrial applications, due to their simple and robust design, high efficiency, and relatively low cost.

A three phase induction motor relies on a rotating magnetic field created by the three-phase power supply. This magnetic field induces a current in the rotor windings, which generates its own magnetic field. The interaction between the rotor and stator magnetic fields produces torque, causing the rotor to rotate.

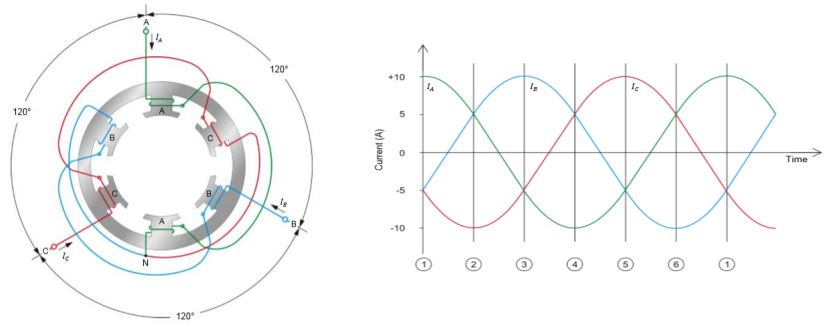

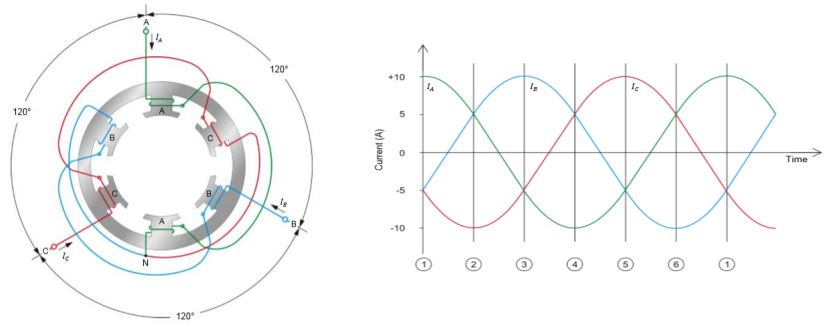

Rotating Magnetic Field

A rotating magnetic field is produced by the combination of sinusoidal currents in each of the stator windings, with a phase difference of 120° between each winding. The resulting magnetic field rotates around the motor at a synchronous speed (Ns), which is calculated using the formula:

Where Ns is the synchronous speed in revolutions per minute (RPM), f is the frequency of the supply in hertz (Hz), and P is the number of poles in the motor.

Step 1: Stator Winding Excitation

When a three-phase power supply is connected to the stator windings, each winding generates a magnetic field. These magnetic fields are sinusoidal in nature and have a phase difference of 120° between each winding. This results in a rotating magnetic field within the stator.

Step 2: Induction of Current in the Rotor

As the rotating magnetic field from the stator passes over the rotor bars, an electromotive force (EMF) is induced in the rotor, according to Faraday’s law of electromagnetic induction. This induced EMF generates currents in the rotor bars, which in turn create their own magnetic field.

Step 3: Interaction Between Stator and Rotor Magnetic Fields

The rotor’s magnetic field interacts with the stator’s rotating magnetic field, creating a torque that causes the rotor to rotate. The direction of the torque depends on the relative direction of the magnetic fields. In a three-phase induction motor, the rotor always tries to follow the rotating magnetic field of the stator.

Step 4: Rotor Slip

In practice, the rotor never reaches the same speed as the stator’s rotating magnetic field (synchronous speed). The difference in speed is known as “slip,” and it is essential for the induction motor to develop torque. If the rotor were to reach synchronous speed, there would be no relative motion between the stator’s rotating magnetic field and the rotor, resulting in zero induced EMF and torque.

The slip (s) is defined as the ratio of the difference between the synchronous speed (Ns) and the rotor speed (Nr) to the synchronous speed:

slip (s) = (Ns – Nr) / Ns

Step 5: Torque-Speed Characteristics

The torque developed by the induction motor is influenced by the slip and the motor’s characteristics. As the slip increases, the torque increases up to a certain point, known as the “maximum torque” or “pull-out torque.” Beyond this point, the torque decreases, and if the slip becomes too high, the motor may stall.

Note: Three-phase induction motors can also be integrated into a motor starter system for better control and protection.

Did you know?

Digital phase converters allow three-phase induction motors to operate using a single-phase power supply. They are particularly useful for applications where a three-phase power supply is unavailable or impractical. They use advanced microprocessor-based control circuits to generate the missing phases, ensuring a balanced and stable three-phase output.

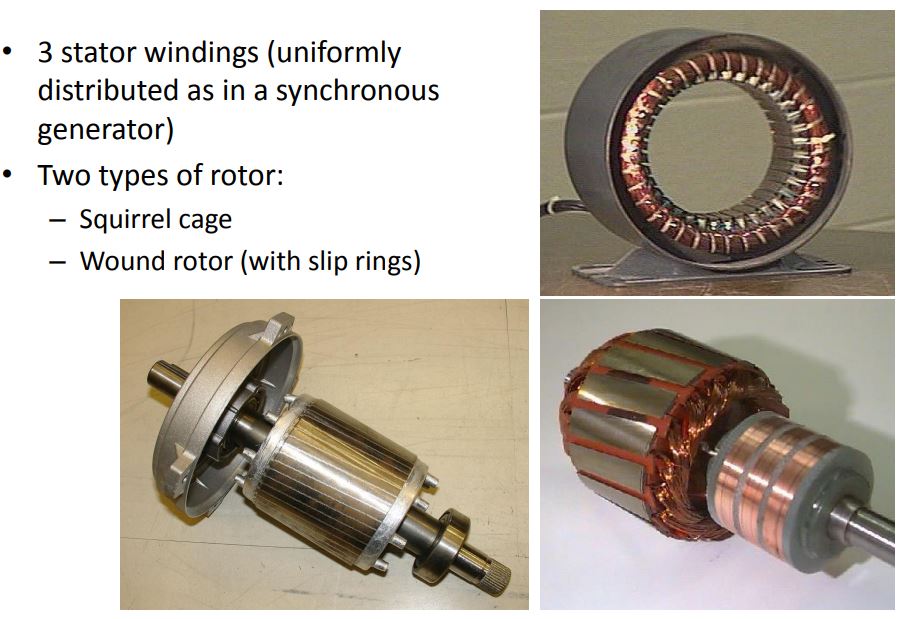

A three-phase induction motor consists of two main parts: the stator and the rotor.

The stator is the stationary part of the motor, which houses the three phase windings. These windings are arranged in slots around the inner circumference of the stator core, which is typically made of laminated iron to reduce eddy current losses.

Elements:

The rotor is the rotating part of the motor, which consists of conductive bars that are shorted at each end by end rings. The rotor can be either a squirrel cage rotor, which is the most common type, or a wound rotor. A squirrel cage rotor has simple construction and requires no maintenance, while a wound rotor has windings similar to the stator and requires slip rings and brushes for operation.

Elements:

There are two main types of three-phase induction motors, classified based on the type of rotor used:

Squirrel cage induction motors, also known as cage rotor induction motors, are the most common type of three-phase induction motors. They are characterized by their simple, robust construction, low cost, and low maintenance requirements.

Wound rotor induction motors, also known as slip ring induction motors, are less common than squirrel cage induction motors. They offer better starting torque and speed control but come with higher maintenance requirements and costs.

There are several types of 3-phase motors, but the three most common types include: Squirrel Cage Induction Motors, Wound Rotor Induction Motors, and Synchronous Motors

The term “induction motor” can refer to both single-phase and three-phase induction motors. However, when people use the term “induction motor” without specifying the number of phases, they are typically referring to a three-phase induction motor, as it is the most widely used type of induction motor in industrial applications.

It is called a 3-phase induction motor because it operates on three-phase alternating current (AC) power, and the torque is generated through the principle of electromagnetic induction. In a 3-phase induction motor, the stator windings are energized by a three-phase power supply, creating a rotating magnetic field that induces currents in the rotor, generating torque and causing the rotor to rotate.

Some advantages of 3-phase induction motors include: High efficiency and power factors, simple and robust construction, self-starting capabilities, high starting torque, wide availability, and the capability to handle heavy loads.

For further information on related topics, consider exploring the following resources: